(Written as a guest post for, and cross-posted from, the Beyond Lean blog.)

Because I’ve driven across the country several times, from one Air Force assignment to the next, I sometimes think in terms of the nation as a whole and forget just how big some states are. Last week I helped the NC State University Industrial Extension Service (IES) conduct the “Manufacturing Makes It Real” tour, covering over 1100 miles in 5 days, and trust me: North Carolina is a pretty big state.

The central message of the tour was that manufacturing — the actual production of durable and consumer goods — matters to all of us, because it is the source of almost everything we have and almost everything we do. As Dr. Terri Helmlinger Ratcliff, IES Executive Director, wrote before the tour, “Manufacturing makes the difference between imagination and reality in ways that make modern life possible.” Invention creates new products, but manufacturing brings them into all our lives.

To spread the message about how much manufacturing matters, we went to every region of North Carolina: the piedmont, the mountains, and along the coast. As we traveled, we held rallies where manufacturers showed off their products and praised their workers. The host sites made the rallies truly “local” events: some had employees sing the National Anthem, some invited Junior ROTC or other school groups to perform, and one invited the local area’s apple orchards to bring some of their products for attendees to sample. Local, State, and even Federal elected officials attended various events, which usually included plant tours to show off the host sites’ capabilities in more detail.

Our convoy included a tractor-trailer with dozens of different “Made in NC” items that showed off the diversity of products made throughout the state. At each rally, people lined up to walk through the trailer to see their handiwork as well as others’. Many people expressed surprise at the variety of products made in the state: “from tortilla chips to microchips,” as IES Deputy Director Dr. David Boulay said.

I like to think the individual rallies were like “county fairs” for manufacturing, and we were pleased at the number of companies that attended, even though we didn’t have blue ribbons to award. And considering the weather we had — record levels of rain along the coast, making us travel on nearly-flooded roads* — we were very fortunate to make it to each stop and hold each rally on time.

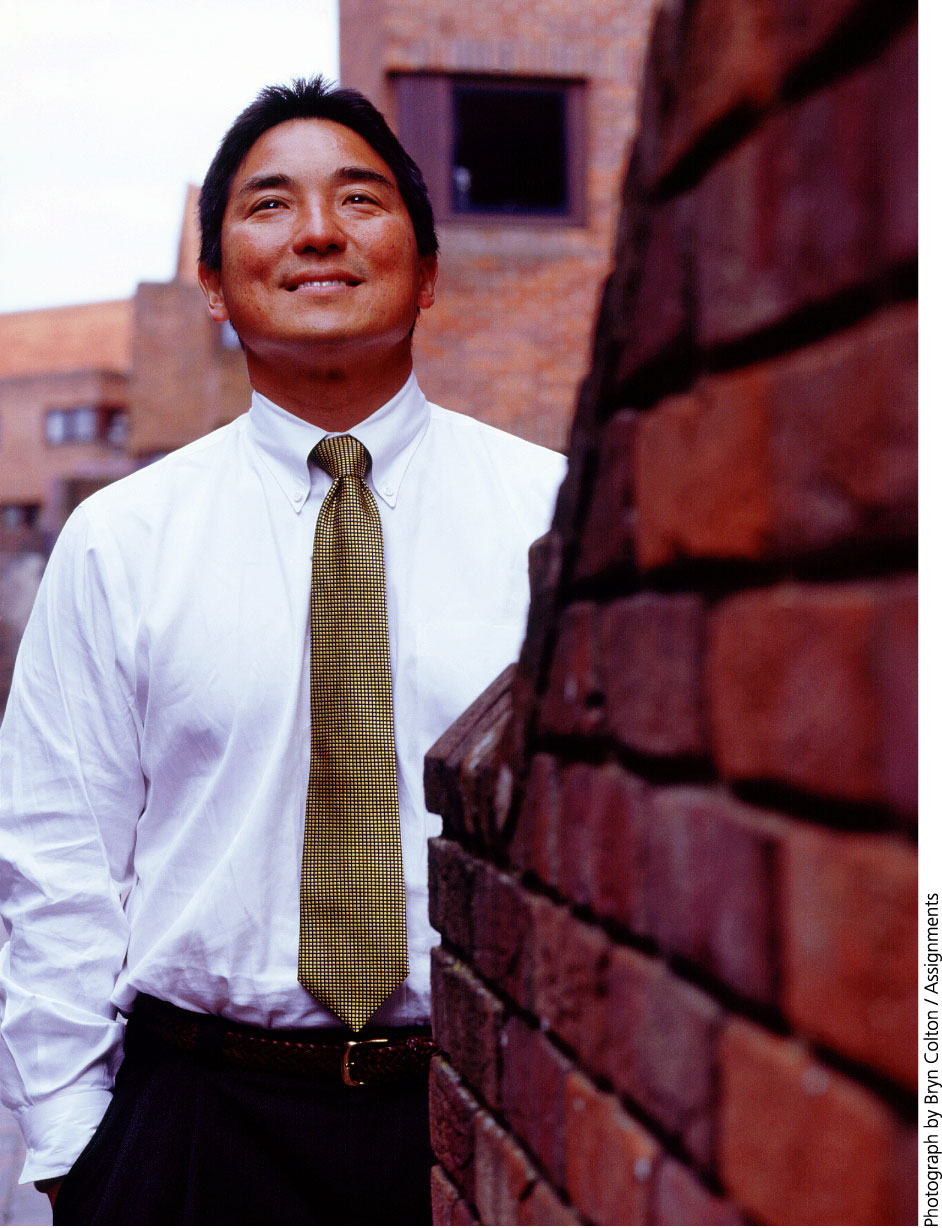

(The Monroe Fire Department’s flag display at Scott Health & Safety. NCSU photo. Click to enlarge.)

The most memorable rally for me was held at Scott Health & Safety in Monroe (east of Charlotte). The Monroe Fire Department had set up two ladder trucks and suspended a huge U.S. flag to help the companies demonstrate their “Made in the USA” pride. That pride-of-workmanship theme was repeated at every stop, but the Monroe event was special to me because I relied on Scott Air Pak breathing gear when I worked disaster response in the Air Force. Their workmanship can literally mean the difference between life and death in dangerous situations. (I wrote more about the Scott Health & Safety rally on the tour blog**).

All week long, from companies big and small and representing many different industry sectors, we heard stories of continuous improvement through lean and Six Sigma, expanded markets through ISO certification, and risk-taking through entrepreneurial ventures and new product development. Company leaders admitted to a lot of belt-tightening and uncertainty in the last couple of years, but seemed pleased that people were paying attention to the good work they do.

The tour ended with a final rally at the NC Legislative Building in Raleigh, where NC State Chancellor Randy Woodson symbolically presented the truckload of products to NC Secretary of Commerce Keith Crisco. The speakers at the final rally, along with the companies that sponsored and participated in the “Manufacturing Makes It Real” tour, testified that manufacturing is alive and well in North Carolina. We are all committed to keeping it that way.

___

*Not complaining! We needed the rain to counteract the summer’s drought.

**For more from the tour blog, including pictures from most of the sites, see http://mfgmakesitreal.wordpress.com/.

by

by